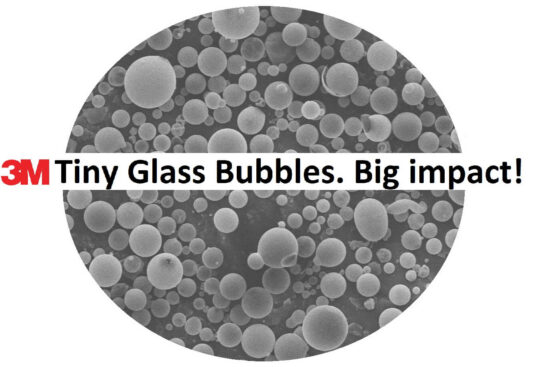

3M Glass Bubbles are used as additives in an astonishing variety of products. For example, they can be formulated into quick-drying, low-shrinkage spackling and other construction materials. They provide a wide range of additional benefits in applications ranging from sporting goods to solar reflective paint. As an ingredient in the plastic parts of your car, glass bubbles help reduce vehicle weight- improving fuel efficiency. 3M Glass Bubbles can reduce the weight of cement used to reinforce oil wells and are used in underwater pipe insulation, making it possible to extract more oil from the bottom of the sea. Around the world, 3M Glass Bubbles are helping to increase productivity…meet new design challenges…enhance product performance…and turn “what’s possible” into “what’s next.”

The glass technology

Soda Lime Glass

Soda lime glass is the “original” glass, appearing in its most basic form thousands of years ago. It is also known as crown glass, a high-silica form of soda lime that was historically used for windows. Soda lime glass is composed of SiO₂, sodium oxide (soda) and calcium oxide (lime). Soda lime glass consists of about 90% of the glass used in the world, including most windows, dinnerware, lighting products, and, well, as well as in bottles and glasses!

Borosilicate Glass

Borosilicate glass is an “engineered” glass developed specifically for use in laboratories and applications where thermal, mechanical and chemical conditions are too harsh for standard, household-type soda lime glass. Some common names of borosilicate are Pyrex™ by Corning and Duran™ by Schott Glass. Like most glasses, the main component of borosilicate glass is SiO₂. The big difference is it has boron oxide and various other specialty elements instead of “soda and lime” to give it its outstanding qualities.

3M Soda Lime Borosilicate Glass Bubbles

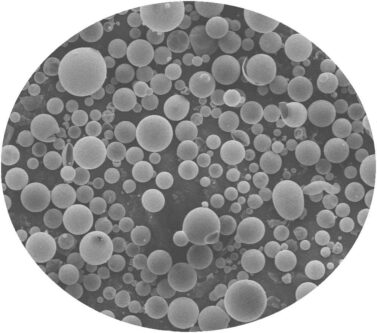

3M Soda Lime Borosilicate Glass Bubbles are made from a combination of borosilicate glass and soda lime glass, so they combine purity with durability, while being chemically inert and water resistant. 3M Glass Bubbles feature a smooth, nonporous surface, and their spherical shape offers a variety of advantages over irregularly shaped additives or conventional fillers. The chemically stable soda-lime-borosilicate glass composition of 3M Glass Bubbles provides excellent water resistance to create more stable emulsions. They are also non-combustible and nonporous, so they do not absorb resin. And, their low alkalinity gives 3M Glass Bubbles compatibility with most resins, stable viscosity and long shelf life.

Find more about