The GGBS material (granulated fly ash) is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam. The final material is the granulated slag (GGBS) that comes from the boiler extinguishing while for the grinding process a granulator is used.

General description

GGBS material is a high whiteness additive used in combination with Portland cement to produce superior quality concrete and other cementitious mortars (Fig.1). Its share in building mortar can reach – in weight – of up to 70%, according to I.S EN 206-1.

Features – Benefits

GGBS material is a calcareous fine powder with hydraulic and pozzolanic properties. It consists mainly of active calcium oxide (CaO), active silicon oxide (SiO2) and aluminum oxide (Al2O3). The remaining part could contain iron oxide (Fe2O3) and other compounds.

The combination of GGBS in the production of cementitious mortars and concrete provides important features during the application and the final result, such as:

- Ease of use: Makes mixing easier

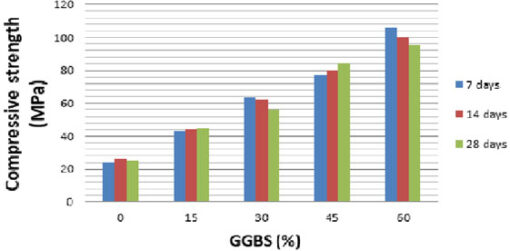

- Resistance to compression forces of the application, especially at high temperatures.

- Lower hydration temperature: Reduces the risk of thermal cracking.

- Reduction of water permeability and porosity, improving the durability of cement.

- Resistance to sulphides: Increases the life-duration of the building.

- Chloride resistance: Helps reduce the solubility of residues, such as chlorides.

- Protection against pH imbalance in cement construction.

- White color: Reduces the requirement of pigment and creates a better aesthetic finish.

- Final result: Fewer defects and smoother surface finish.

Figure 1. GGBS impact on the compressive strength of a geopolymer sample (Source: Apriany Saludung et al, 2018).

The chemical composition of the material offered by our company is as follows:

Benefits of GGBS in concrete

- Lower permeability.

The higher silica and lower lime content in GGBS achieves a denser binder mixer formation, resulting in lower porosity and improvement of physical immobilisation of contaminants (Fig.2).

- Increased long-term durability.

GGBS achieves higher long-term durability than regular Portland cement and extends the life-duration of project structures.

- Resistance to sulphates and acids.

GGBS replaces the use of sulphate-resistant Portland cement (SRPC) due to its excellent resistance to sulphates and acids. GGBS can be used in concrete for all categories of aggressive soil conditions listed in the BRE Special Digest 1: 2005 – Concrete in aggressive soil conditions.

- Lower environmental impact.

The carbon footprint of GGBS is just 42 kg of CO2 per tonne, whereas ordinary Portland cement is over 850 kg CO2 per tonne. GGBS is the only product to have a third party verified Environmental Product Declaration.

- Leachate reduction

The pH of GGBS is lower than cement pH (10-11 compared to 13+ for cement). Thus GGBS, when mixed, lowers the pH of the stabilised matrix, which results in reducing solubility of the contaminants, and minimises leaching (Fig.2).

Ask for more info